Why Osborn Products?

- Aerospace Quality Gages

- Precision CNC Machining & Grinding

- Made in USA

- Established in 1956

Software

The Most Complete & Accurate Screw Thread Engineering Software.

Read our Testimonials Here

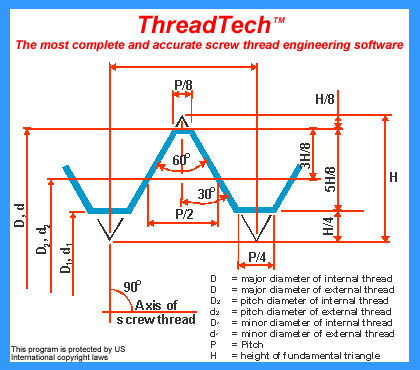

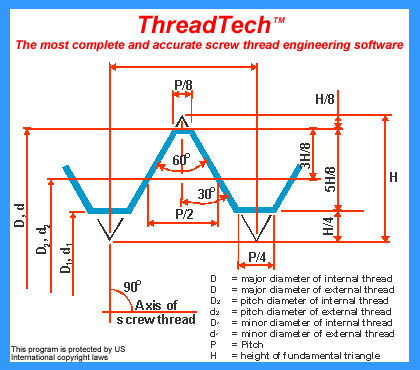

ThreadTech

ThreadTech gives the answer to pitch diameters, minor diameters, gage data, part data, tap data, helix angles, tolerances, crest and root flats, wire sizes, constants and just about anything on screw threads one would like to know.

The program prompts the user with questions which must be answered correctly before continuing to the next question. If the user inputs a dimension that is geometrically impossible or impractical, the program will prompt you until usable data is input. All formulae and rounding techniques are consistent with the latest ANSI, ASME and government specifications. When calculated values don't agree with table values, the program displays the table values. Easy to use

No computer skills are necessary to operate the program. The program provides step by step on screen explanations. All data can be easily saved and printed.

The program runs on Windows NT, 2000, XP, VISTA and 7. ThreadTech was designed for engineers, planners, quality assurance and machinist to save time and to help eliminate human error. The comprehensive screw thread program takes confusion out of thread manufacturing and inspection. It takes the place of time consuming computations and searches for specifications.

Download a free 30 day trial. Save the file to your computer. After the download is complete double click on the icon to run Setup.

Call 1-800-767-7633 for a free trial.

ThreadTech Features

THREADTECH™ V2.24 SOFTWARE COMPLIES WITH THE LATEST REVISIONS OF THE FOLLOWING STANDARDS:

Read our Testimonials Here

ThreadTech

ThreadTech gives the answer to pitch diameters, minor diameters, gage data, part data, tap data, helix angles, tolerances, crest and root flats, wire sizes, constants and just about anything on screw threads one would like to know.

The program prompts the user with questions which must be answered correctly before continuing to the next question. If the user inputs a dimension that is geometrically impossible or impractical, the program will prompt you until usable data is input. All formulae and rounding techniques are consistent with the latest ANSI, ASME and government specifications. When calculated values don't agree with table values, the program displays the table values. Easy to use

No computer skills are necessary to operate the program. The program provides step by step on screen explanations. All data can be easily saved and printed.

The program runs on Windows NT, 2000, XP, VISTA and 7. ThreadTech was designed for engineers, planners, quality assurance and machinist to save time and to help eliminate human error. The comprehensive screw thread program takes confusion out of thread manufacturing and inspection. It takes the place of time consuming computations and searches for specifications.

Download a free 30 day trial. Save the file to your computer. After the download is complete double click on the icon to run Setup.

Call 1-800-767-7633 for a free trial.

ThreadTech Features

- Uses latest government and industry specifications

- 60 degree inch and metric threads

- Acme, Pipe, STI, British & American buttress threads gages and ISO metric trapezoidal threads gages

- British Pipe Gages and Parts per ISO 228 -1 and ISO 228-2

- British Tapered Pipe Gages and Parts per ISO 7-1 and ISO 7-2

- Threads for thread plug gages, thread ring gages, and thread setting plug gauges

- Default sizes to agree with specifications

- All diameters, angles, roots, flats

- Pitch diameters

- Minor diameters

- Helix Angles

- Worm gearing calculations utilize Buckingham and Vogel Formulas (various included angles)

- Gage Data

- Part Data - internal and external threads

- Tap Data for inch and metric

- Product and gage tolerances

- Crest and root flats

- Wire sizes and constants

- Measurement over wires data

- Standard plating using max, min, or nominal

- Anodize plating calculates penetration

- HAE plating

- Metric and inch equivalents for double dimensioning

- Table and computed values

- Length of engagement

- Warning alerts and halts for geometrically impossible dimensions and plating thickness

- DIN Part 3 and Part 9 Trapezoidal threads for parts, ring gages, caliper gages, and plug

THREADTECH™ V2.24 SOFTWARE COMPLIES WITH THE LATEST REVISIONS OF THE FOLLOWING STANDARDS:

- Unified inch screw threads-parts: ASME B1.1

- Unified inch screw threads-gages: ASME B1.2

- Unified inch screw threads (UNJ Thread Form): ASME B1.15

- Screw threads - UNJ profile, inch: AS8879D

- Unified inch taps : ASME B94.9

- S.T.I. screw thread plug gages: MIL-T-211309 / A-A-59158

- Metric screw threads M profile-parts: ASME B1.13M

- Metric screw threads M profile-gages: ASME B1.16

- Metric screw threads MJ profile-parts: ASME B1.21M

- Metric screw threads MJ profile-gages: ASME B1.22M

- Metric taps: ASME B94.9

- Buttress inch screw threads-parts and gages: ANSI B1.9

- NPT pipe threads: ASME B1.20.1

- ANPT pipe threads: SAE AS7105

- NPSC pipe threads: ASME B1.20.1

- NPTR pipe threads: ASME B1.20.1

- NPSM pipe threads: ASME B1.20.1

- NPTF pipe threads-parts: ASME B1.20.3

- NPTF pipe threads-gages: ASME B1.20.3

- Pipe threads where pressure-tight joints are not made on the threads-Parts: ISO 228-1

- Pipe threads where pressure-tight joints are not made on the threads-Gages: ISO 228-2

- Pipe threads where pressure-tight joints are made on the threads Parts: ISO 7-1

- Pipe threads where pressure-tight joints are made on the threads Gages: ISO 7-2

- Worm threads: Vogel Formula, Buckingham Formula

- Acme screw threads-general purpose and centralizing-parts and gages: ASME B1.5

- Stub acme screw threads-parts and gages: ASME B1.8

- ISO metric trapezoidal-parts: DIN 103 part 3

- SO metric trapezoidal-gages: DIN 103 part 9'

- Universal Screw Thread Program: EA-10/10 Berndt equation, Vogel exact equation